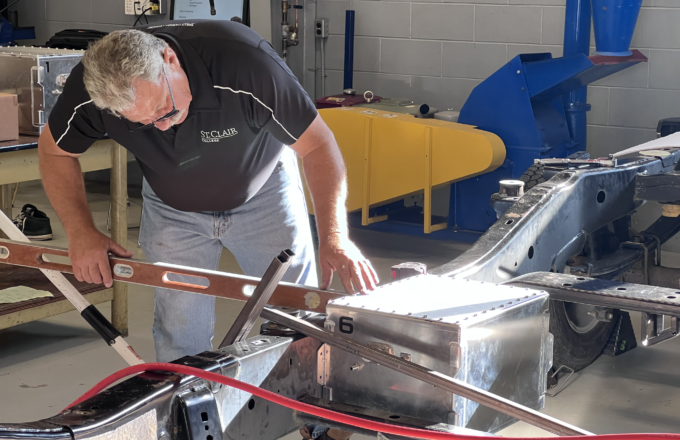

The Enwin EV team have been busy converting one of its fleet vehicles from an internal combustion engine (ICE) to an all-electric drive train. An interesting fact about the electric drive train, despite the small size of this electric motor, did you know it will produce more than its ICE predecessor and it is light enough for one person can lift!

A lot of fascinating, high-tech equipment is being used during this project. Last week the team continued using a 3D scanner to capture accurate measurable 3D data of the interior of the vehicle to create a plan to install new dash-mounted components. The purpose of these 3D scans is to be able to work with a digital model in preparation for alterations to the design, and installation of the new components.

There are also four state-of-the-art mobile, wireless lifts being used. They are positioned freely throughout the floor to accommodate the ever-changing floor plan and tasks at hand, creating a nimble environment as the project progresses.

Another interesting fact! Custom components were fabricated using a plasma cutter (a machine used in all sorts of metal fabrication projects) and a CNC wire Electrical Discharge Machine which uses a travelling wire electrode that physically passes through the workpiece. Some components created were customized mounts.

Be sure to stay tuned for more updates, photos and videos to come.![]()

![]()

![]()

![]()